RojoRacing

Donut Powered Wise-guy

Ok for those of you who have been following my road to 500 miles thread you have read of my struggles with the stock headrest. So over the last week I've brainstormed several ideas that in effect will accomplish two things.

1st Keeping the headrest in contact with the neck up to the base of the skull and no higher to avoid discomfort from helmet interference.

2nd Adding a small amount of shock absorption to bumps in the road that with the stock headrest makes it feel like someone just hit you with a baseball bat with every sharp bump.

My first idea was a plate system made from spring steel and after some searching around I found that someone was already making a system similar to what I was thinking but out of aluminum instead. I liked their execution of the idea but with a lack of up and down adjustment I didn't want to spend the $150 on something I may not be 100% happy with, plus I have my own sheet metal shop so I can make as many prototypes as I want till it's perfect. I was doing just that this morning when another idea popped into my head. Why a foam pad? No matter what grade of pad you use there will always be spots of high and low pressure that can lead to discomfort so why not ditch the pad for suspension? If I make a small leather hammock in just the right place it should be light enough for racers and comfortable enough for tourist.

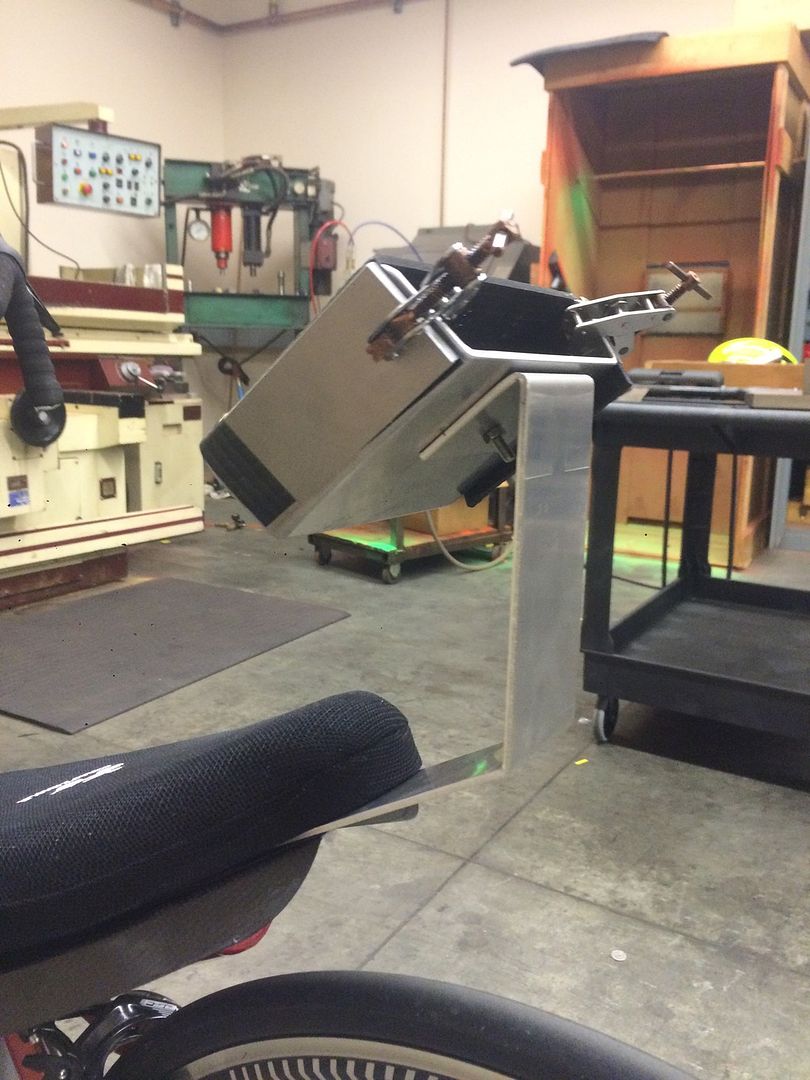

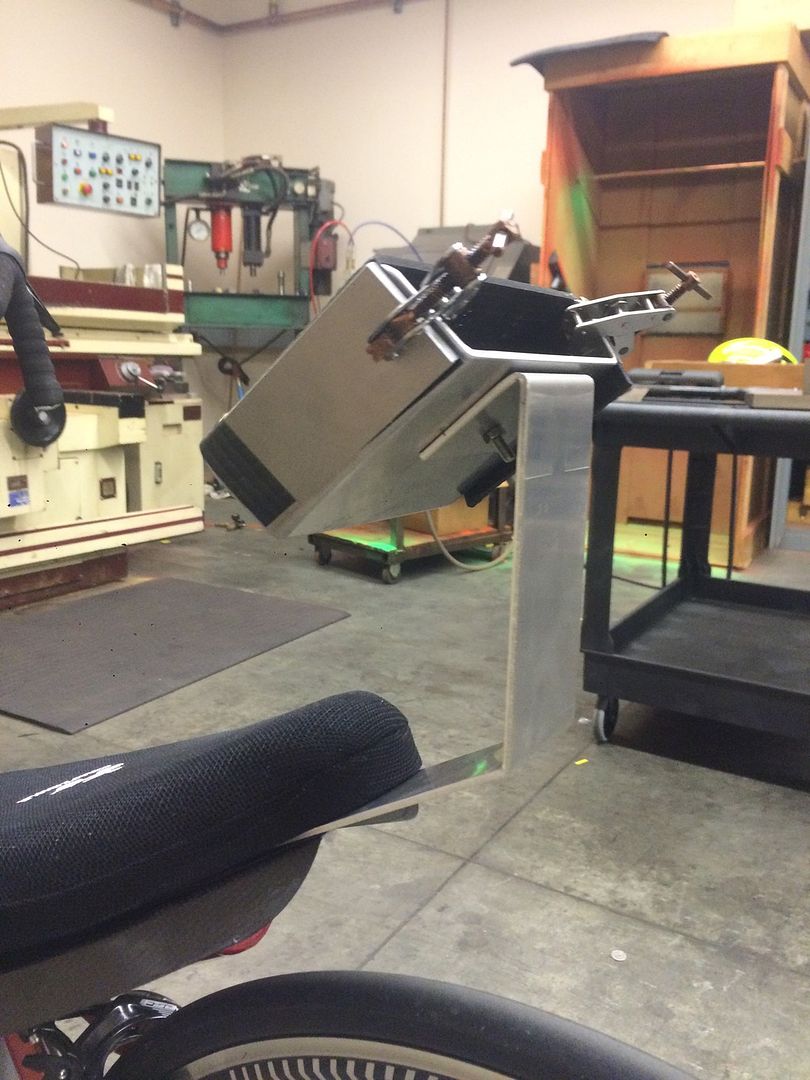

Here's what I've got so far and obviously I lack the proper leather material for the hammock part but I can make do with some foam toolbox drawer liner for now. My first impression is extremely positive and I can't wait to fine tune it a bit more so I can take it for a spin.

With the new hammock idea I don't think I'll need the spring of the spring steel so I may just stay with the 1/8" aluminum. If you guys and gals have an ideas or suggestions nows the time to speak up so I can still change my design as I go.

1st Keeping the headrest in contact with the neck up to the base of the skull and no higher to avoid discomfort from helmet interference.

2nd Adding a small amount of shock absorption to bumps in the road that with the stock headrest makes it feel like someone just hit you with a baseball bat with every sharp bump.

My first idea was a plate system made from spring steel and after some searching around I found that someone was already making a system similar to what I was thinking but out of aluminum instead. I liked their execution of the idea but with a lack of up and down adjustment I didn't want to spend the $150 on something I may not be 100% happy with, plus I have my own sheet metal shop so I can make as many prototypes as I want till it's perfect. I was doing just that this morning when another idea popped into my head. Why a foam pad? No matter what grade of pad you use there will always be spots of high and low pressure that can lead to discomfort so why not ditch the pad for suspension? If I make a small leather hammock in just the right place it should be light enough for racers and comfortable enough for tourist.

Here's what I've got so far and obviously I lack the proper leather material for the hammock part but I can make do with some foam toolbox drawer liner for now. My first impression is extremely positive and I can't wait to fine tune it a bit more so I can take it for a spin.

With the new hammock idea I don't think I'll need the spring of the spring steel so I may just stay with the 1/8" aluminum. If you guys and gals have an ideas or suggestions nows the time to speak up so I can still change my design as I go.